Exploring ERP vs. PLM: Optimizing Fashion's Tech Foundation

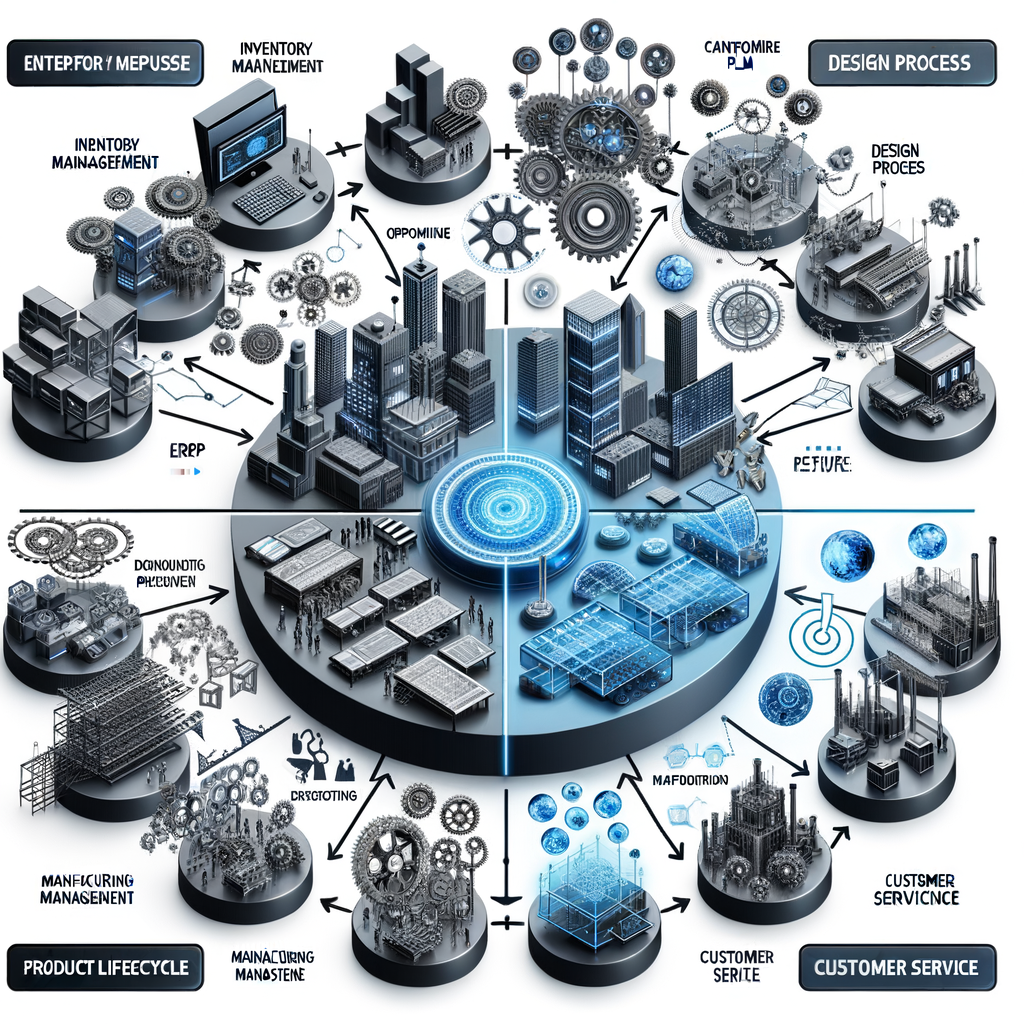

The fashion industry relies on complex systems to manage design, production, and distribution. Two important technologies that have become invaluable are enterprise resource planning (ERP) systems and product lifecycle management (PLM) software. Though they share some similarities, ERP and PLM serve different primary purposes.

ERP systems integrate core business processes including manufacturing, logistics, finance, supply chain, and human resources. ERP helps fashion companies manage operations and data across departments. It provides visibility and control across the entire organization.

On the other hand, PLM software manages product data through the full lifecycle from concept to consumer. PLM enables collaboration across product development teams. It manages Bill of Materials (BOM), tech specs, compliance, calendars, costing, and other product-related information.

For fashion brands and retailers, ERP and PLM work best together. ERP focuses on back-end resource planning while PLM handles front-end product development. But companies need to understand the key differences between the two systems to determine which applications suit their needs.

This article will compare ERP and PLM for fashion companies. It will cover the unique capabilities of each system and how they complement one another. Case studies will demonstrate how leading fashion houses leverage ERP and PLM to bring innovative products to market faster and more efficiently.

Understanding ERP Systems

Enterprise Resource Planning (ERP) systems are business process management software that integrates various organizational functions into a unified system. ERP collects data from different departments across a company and stores it in a central database. It facilitates information sharing and provides reporting and analytics capabilities.

Some key functions of ERP systems include:

- Financial Management - ERP handles accounting, cost management, budgeting, payment processing, and other financial data.

- Supply Chain Management - ERP oversees procurement, inventory, warehousing, order fulfillment, logistics, and supplier management.

- Manufacturing - ERP systems schedule production capacity, materials, labor, and monitor shop floor operations.

- Human Resource Management - ERP stores employee data, payroll, recruitment, training, and other HR functions.

- Customer Relationship Management - ERP collects customer data and enables customer service activities.

- Reporting and Analytics - ERP generates reports for business intelligence and planning across departments.

For fashion companies, ERP helps connect sales orders to production and procurement. It provides real-time visibility into inventory levels and supply chain activities. ERP streamlines back-office operations to help fashion brands and retailers get products manufactured, distributed, and delivered efficiently.

Leading ERP systems for the fashion industry include Oracle NetSuite, SAP S/4HANA, Infor CloudSuite Fashion, and Microsoft Dynamics 365. Choosing the right solution depends on the company’s size, budget, and business requirements.

Understanding PLM Systems

Product Lifecycle Management (PLM) software helps fashion companies manage product-related data and processes from initial concept to consumer purchase. PLM creates a central repository for all product information that can be accessed across the enterprise.

Key capabilities of PLM systems include:

- Product Design - PLM centralizes product design data including sketches, tech packs, Bill of Materials (BOM), specifications, prototypes, and more.

- Collaboration - PLM enables collaboration between designers, product managers, developers, manufacturers, and other teams.

- Portfolio Management - PLM provides a single view of all products across seasons, categories, brands, and markets.

- Materials Management - PLM manages materials like fabrics, trims, labels, and tracks compliance certificates.

- Calendar and Milestone Management - PLM oversees critical paths, calendars, workflows, and deadlines.

- Costing - PLM factors in cost estimates, purchase orders, margins, and landed costs.

- Sustainability - PLM assesses sustainability initiatives, chemical usage, and compliance.

- Analytics - PLM generates reports on product development performance.

For fashion, PLM is essential for getting new styles to market quickly while maintaining quality and control. It connects design concepts to production and sourcing execution. PLM improves time-to-market, increases efficiency, and reduces product failures.

Leading PLM solutions for fashion include Centric, Gerber, Lectra, and Infor. The ideal solution depends on the company’s product complexity, size, budget, and specific goals.

Key Differences Between ERP and PLM

While ERP and PLM both provide major benefits for fashion companies, they serve different primary purposes. Here are some key differences between the two systems:

- Scope - ERP focuses on back-end operations like manufacturing, supply chain, and finance. PLM concentrates on front-end product development.

- Data - ERP handles transactional and numerical data like orders, inventory, and costs. PLM manages unstructured product data like images, drawings, and specifications.

- Processes - ERP oversees core business processes that span departments. PLM manages product-related processes within design and development.

- Users - ERP serves finance, operations, HR, and other enterprise users. PLM is for product teams including designers, developers, and marketers.

- Implementation - ERP follows a sequential phased approach by module. PLM can be implemented faster focusing on key pain points.

- Customization - ERP configurations support best practices while PLM requires customization for product variance.

- Timelines - ERP has longer planning and rollout timelines. PLM can demonstrate ROI faster.

- Reporting - ERP offers real-time insights into business performance. PLM provides product analytics.

- Vendors - Major ERP vendors include SAP, Oracle, Microsoft. PLM vendors like Centric and Gerber specialize in fashion.

While their core functions differ, ERP and PLM can exchange critical data. PLM product data can feed into ERP for sourcing, costing, and production. ERP data can input into PLM for timelines and resource availability. The two systems complement each other for end-to-end fashion industry management.

ERP Functions for Fashion Companies

ERP systems provide a multitude of benefits for fashion brands and retailers. Here are some of the key capabilities ERP offers:

- Demand Planning - ERP uses historical sales data, forecasts, and inventory levels to predict future demand more accurately. This enables better allocation of materials and resources.

- Procurement and Sourcing - ERP manages vendor selection, purchase orders, procurement costs, and supplier relationships. This optimizes spending on materials and services.

- Supply Chain Execution - ERP oversees distribution, logistics, and inventory tracking from sourcing to store delivery. This improves visibility and helps avoid stockouts.

- Production Management - ERP schedules production capacity, labor, equipment, and shop floor execution. This helps maximize throughput and on-time delivery.

- Financial Management - ERP automates invoicing, collections, expense accounting, and other financial processes. This provides real-time insight into profitability.

- Omnichannel Management - ERP connects inventory, order fulfillment, and customer data across brick-and-mortar and ecommerce channels. This enables unified commerce.

- Business Intelligence - ERP provides reporting and dashboards for data-driven decision making across departments and locations.

By integrating all of these capabilities into a single solution, ERP enables fashion brands and retailers to improve efficiency, scalability, and flexibility across the enterprise. ERP is essential for supporting complex global operations and accelerating growth.

PLM Functions for Fashion Companies

PLM software provides invaluable capabilities for fashion brands managing thousands of product styles each season:

- Concept Design - PLM enables designers to collaborate on initial sketches, colorways, silhouettes, and creative concepts digitally.

- Tech Pack Management - PLM centralizes tech packs with all product specifications, materials, construction, and compliance requirements.

- Project Planning - PLM generates calendars, milestones, workflows, and critical paths for every product launch. This improves on-time delivery.

- Costing - PLM factors in bill of materials, purchase costs, labor, logistics, duties, and margins for accurate cost estimates.

- Sourcing - PLM shares tech pack data with vendors to source accurate materials and services for production.

- Quality Assurance - PLM manages product testing, sample approvals, compliance certificates and supports factory audits.

- Materials Management - PLM maintains materials libraries, consolidates purchases across products, and tracks usage.

- Supplier Collaboration - PLM portals allow suppliers to access tech packs and submit samples, documents and updates.

- Sustainability - PLM assesses materials, chemical usage, social compliance, and other sustainability initiatives.

- Analytics - PLM provides reports and KPIs on product development performance for continuous improvement.

By centralizing all product data in a single system, PLM empowers fashion companies to streamline operations, reduce errors, maintain quality, and accelerate time-to-market. PLM is critical for managing product complexity and growth.

Deciding Between ERP and PLM for Fashion

When exploring new technology for their businesses, fashion companies need to take a strategic approach to selecting between ERP and PLM systems. Here are some considerations when deciding:

- Current Systems - Assess existing processes and systems. Determine pain points and gaps that need to be addressed.

- Business Needs - Prioritize between optimizing back-end operations versus front-end product development.

- Budget - ERP and PLM both require significant investments. Define budget parameters.

- Timelines - ERP may take longer to rollout while PLM can demonstrate ROI quicker.

- Capabilities - Review feature sets needed for finance, supply chain, product development etc.

- Data Integration - Consider how to connect ERP and PLM data for information sharing.

- Ease of Use - Evaluate interfaces and customization requirements for different user types.

- Scalability - Ensure the solution can support business growth over next 5-10 years.

- Total Cost of Ownership - Factor in implementation, customization, training, and ongoing costs.

- Cloud vs On-Premise - Cloud-based systems enable mobility and rapid updates.

By identifying their top priorities and constraints, fashion companies can determine whether to implement ERP, PLM or an integrated ERP and PLM solution. This enables the right technology choice to meet strategic goals.

Implementing ERP or PLM for Fashion

Once fashion companies select an ERP or PLM solution, thoughtful implementation is crucial for adoption success. Here are some best practices:

- Develop a Roadmap - Create a project plan and timeline spanning solution design, testing, training, data migration, and go-live.

- Assemble Implementation Team - Include subject matter experts from business units and IT/digital teams. Third party integrators can also provide support.

- Analyze and Clean Data - For data migration, audit existing data for accuracy and integrity. Clean up outdated, duplicate or incorrect information.

- Minimal Viable Product - Focus initial rollout on priority processes and test rigorously before expanding features.

- Perform Integration Testing - Test data flows between new and legacy systems to ensure bidirectional syncing.

- Conduct User Training - Provide onboarding, online learning resources, videos and quick reference guides tailored to each user role.

- Define Metrics and KPIs - Establish quantifiable metrics aligned to business objectives to track performance and adoption.

- Monitor and Refine - Continuously gather user feedback to identify enhancements and new use cases over time.

With proper planning and change management, fashion companies can ensure ERP and PLM deliver value from initial launch and over the long term. Ongoing training and engagement are critical for driving user adoption at scale.

Case Studies of Fashion Companies Using ERP/PLM

Let’s examine how major fashion companies have leveraged ERP and PLM solutions:

Louis Vuitton

- Implemented cloud-based PLM from Centric Software to manage thousands of SKUs across leather goods, shoes, accessories and more.

- Reduced product development cycles by 15%. Enabled real-time collaboration with suppliers.

- Integrated PLM with SAP ERP for end-to-end operations.

H&M

- Selected Infor CloudSuite Fashion PLM to replace legacy PLM and connect global teams.

- Accelerated time-to-market by up to 20% through improved collaboration.

- Leveraged PLM integration with ERP system for costing, planning and execution.

Ralph Lauren

- Deployed PLM from FlexPLM and integrated with SAP ERP.

- Achieved year-over-year growth with streamlined operations and sourcing.

- Enabled digital collaboration and maintained quality standards consistently.

Lululemon

- Adopted PLM solution from Centric Software.

- Gained real-time visibility into product development and materials sourcing.

- Seamless integration with NetSuite ERP improved supply chain efficiency.

Through best-in-class technology, leading fashion houses drive product innovation, shorten lead times, and boost profitability. Tight integration between ERP and PLM unlocks supply chain optimization and digital transformation.

Conclusion

ERP and PLM serve critical but distinct purposes for fashion companies. ERP integrates back-end operations like supply chain, manufacturing, and finance while PLM manages front-end product development from concept to consumer.

Though their capabilities differ, ERP and PLM can complement one another through open API integration. ERP provides the operational data that PLM needs for product costing, timelines, and sourcing. PLM shares product data that feeds into ERP for production planning and inventory management.

Together, tightly integrated ERP and PLM enable fashion brands to accelerate new product introductions, maintain quality, and improve visibility across the value chain. This leads to higher margins, faster growth, and leaner operations.

When exploring ERP and PLM, fashion companies should start by identifying pain points and top business priorities. Comparing solution capabilities and mapping integration needs is essential for determining the optimal technology investments.

With the right strategy and implementation approach, fashion companies can leverage ERP and PLM to gain a true competitive advantage. By digitally transforming core business processes and product development, fashion brands can exceed customer expectations and outpace the competition through technology.

-500x500.jpg)

-500x500.jpg)

-500x500.jpg)

-500x500.jpg)

-500x500.jpg)