Effortless OEM Clothing Startup: Maximize Profits Now

Embarking on an entrepreneurial journey in the fashion industry can be an exhilarating yet daunting task. The allure of creating a brand that resonates with consumers and stands out in the marketplace is a powerful motivator. However, the pathway to success is often paved with challenges and requires a blend of creativity, strategy, and a keen understanding of the market mechanics.

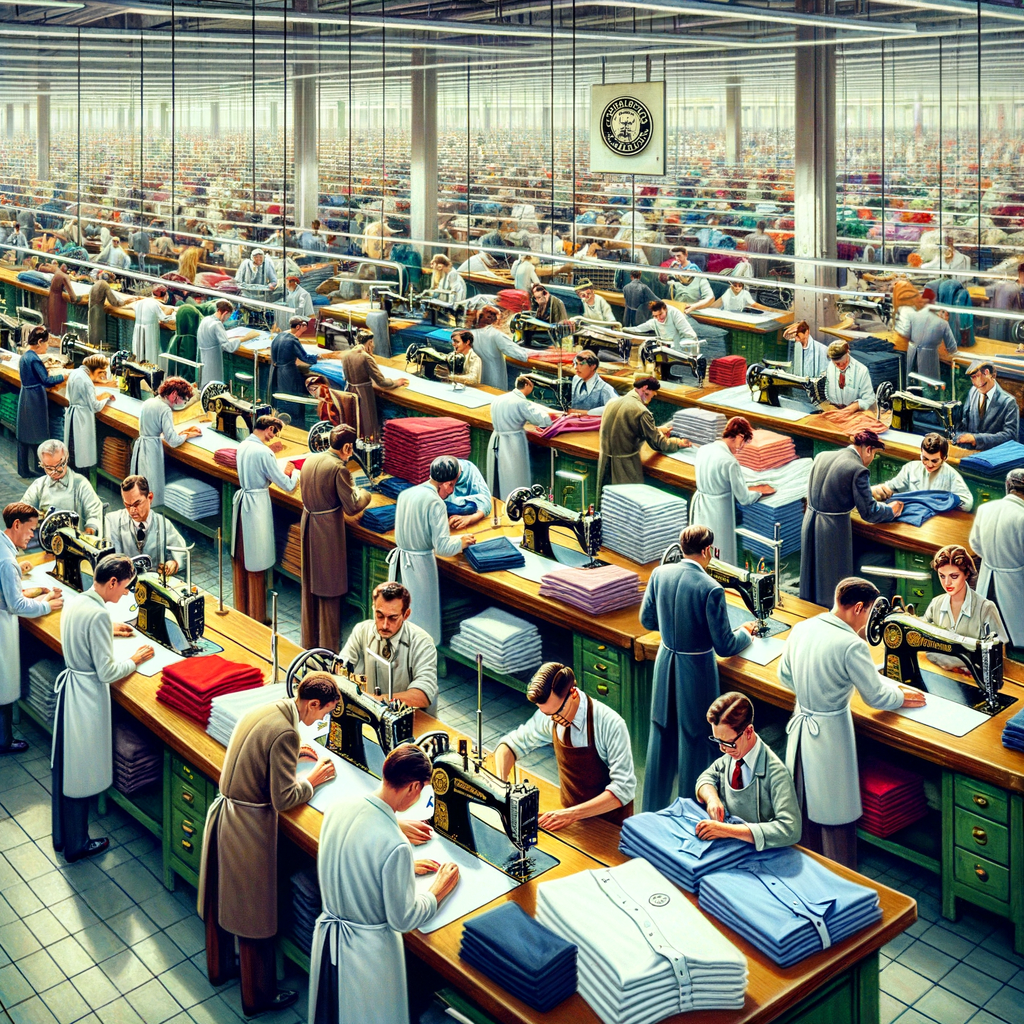

Starting an Original Equipment Manufacturer (OEM) clothing business presents a unique opportunity. This business model involves manufacturing products as per the specifications provided by another company, which then sells the products under their own brand name. The advantages of this approach include lower development costs, the ability to focus on production excellence, and the potential to establish long-term partnerships with established brands seeking quality manufacturing services.

In this endeavor, the goal is to streamline the process, minimizing effort while maximizing profit. Achieving this balance necessitates careful planning, a deep understanding of the industry, and the capability to anticipate and adapt to market trends.

The aim of this article is to offer a comprehensive guide that navigates through the various aspects of setting up an OEM clothing manufacturer business. From identifying your niche and sourcing materials to establishing efficient production and crafting compelling marketing strategies, this article will provide valuable insights and actionable steps to help you build a profitable venture with a strong foundation.

Understanding the OEM Clothing Manufacturing Industry

To embark on the journey of starting an OEM clothing manufacturer business, one must first comprehend the landscape of the industry. An OEM arrangement allows you to specialize in the manufacturing process while your partner company focuses on brand development, marketing, and sales, creating a symbiotic relationship that can lead to mutual success.

The clothing manufacturing industry has evolved dramatically with technology advancements and global trade. Today's consumers demand high-quality garments at competitive prices, and retailers are constantly looking for reliable manufacturers who can deliver these needs.

Key Industry Insights:

Global Reach: Clothing manufacturing has a global footprint, with production hubs in countries like China, Bangladesh, India, and Vietnam due to their cost-effective labor and established supply chains. However, there is a growing trend towards near-shoring to regions like Eastern Europe and Central America, which can offer faster turnaround times and lower shipping costs.

Technological Advancements: Automation and digitalization are transforming the industry. From computer-aided design (CAD) to automated cutting and sewing machines, embracing technology can significantly reduce production times and costs.

Sustainability Concerns: There is an increasing push towards sustainable and ethical manufacturing practices. Consumers and brands are more environmentally conscious, demanding transparency and responsibility in the production process.

Entry Barriers and Opportunities:

Capital Investment: Starting a manufacturing business typically requires significant capital investment in machinery, materials, and facilities. However, technological innovations like 3D printing and lean manufacturing can help new entrants minimize these costs.

Specialization: The industry favors manufacturers that specialize in certain types of clothing or materials, which can lead to higher efficiency and better quality control.

Regulations and Compliance: Understanding and adhering to international trade regulations, labor laws, and safety standards is critical to operate smoothly and avoid costly legal issues.

Market Research and Identifying Your Niche

Before immersing yourself in the complexities of the OEM clothing manufacturing business, conducting comprehensive market research is a non-negotiable step. This phase is critical to identify a niche that not only resonates with your business vision but also offers a competitive edge in the market.

Conducting Market Research:

Trend Analysis: Stay abreast of current fashion trends and future forecasts. Tools like Google Trends, fashion magazines, and industry reports can provide insights into emerging styles and consumer preferences.

Competitor Analysis: Evaluate existing OEM manufacturers. Understand their strengths, weaknesses, and market positioning. Identify gaps in the market that your business could potentially fill.

Customer Identification: Determine who your potential clients are. Are you targeting small boutique brands, mid-level fashion labels, or high-end designers? Understanding your customer's needs is crucial to tailor your services effectively.

Supply Chain Logistics: Investigate the logistics of sourcing materials and delivering finished products. A good grasp of supply chain management can aid in identifying a niche that aligns with smooth logistical operations.

Identifying Your Niche:

Specialization by Garment Type: Consider specializing in a specific type of clothing, such as activewear, children’s clothing, or formal wear. This can help you focus your production process and appeal to brands in that segment.

Material Specialization: You might also specialize in manufacturing products using a particular material, like organic cotton, recycled fabrics, or high-tech textiles.

Technological Innovation: Offering services that incorporate cutting-edge technology, such as 3D knitting or seamless construction, can distinguish your business in a crowded market.

Customization and Small Batches: As fashion moves towards personalization, there's an opportunity in offering highly customized options or catering to brands that require small batch production.

Crafting a Business Plan

A well-structured business plan is your blueprint for success in the OEM clothing manufacturing industry. It serves as a strategic guide, outlining your business goals, strategies, and how you plan to achieve them. This document is also essential when seeking funding or partnerships as it demonstrates the viability and potential profitability of your business.

Essential Components of Your Business Plan:

Executive Summary: Begin with a clear and compelling summary that encapsulates the essence of your business, your objectives, and what sets you apart from the competition.

Company Description: Provide an in-depth look at your business. Detail the problems you solve, the niche you cater to, and the markets you serve.

Market Analysis: Incorporate your market research data to justify the demand for your manufacturing services. Include information about industry trends, target market demographics, and competitor analysis.

Organization and Management: Outline your business structure, the expertise of your management team, and the roles and responsibilities within your company.

Service Line: Describe the clothing products you will manufacture, highlighting any unique features or proprietary aspects of your production process.

Marketing and Sales Strategy: Detail how you intend to attract and retain clients. Explain your sales process, pricing strategies, and how you plan to build and nurture client relationships.

Funding Request: If you're seeking financing, specify the amount needed, how it will be used, and the preferred terms.

Financial Projections: Offer a financial forecast that includes projected income statements, balance sheets, cash flow statements, and capital expenditure budgets for the next three to five years.

Appendix: Provide supporting documents or additional information, such as resumes of your management team, legal agreements, or detailed market study findings.

Aligning the Business Plan with Your Niche:

Ensure that every aspect of your business plan reflects the niche you've identified. For instance, if you're specializing in eco-friendly materials, your funding request might include investment in sustainable production technologies.

Your marketing strategy should target the specific audience interested in your niche. If your focus is on high-tech sportswear, your marketing should reach out to brands that value technological innovation in clothing.

Sourcing Quality Materials

Sourcing the right materials is pivotal to the success of an OEM clothing manufacturer. The quality of the materials directly impacts the quality of the finished garments, affecting your reputation and the satisfaction of your clients. Establishing reliable supply chains and vendor relationships is key to ensuring consistent quality and timely delivery of products.

Developing a Sourcing Strategy:

Supplier Research: Identify potential suppliers who can provide the materials you need. Consider factors such as quality, cost, reliability, and ethical practices.

Samples and Testing: Request samples from several suppliers and conduct rigorous testing to assess quality, durability, and suitability for your manufacturing needs.

Negotiating Terms: Once you've selected suppliers, negotiate terms that balance cost with flexibility, such as minimum order quantities, payment terms, and delivery schedules.

Diversification: Avoid relying on a single supplier for all your materials. Having multiple sources can protect your business from supply disruptions.

Considerations for Material Quality:

Compliance with Standards: Ensure the materials meet industry standards and regulations, such as ISO (International Organization for Standardization) certifications for quality management.

Sustainability: If your niche involves sustainability, source materials certified by organizations like GOTS (Global Organic Textile Standard) or bluesign®.

Client Specifications: Align material choices with the specific needs and quality expectations of your clients. Their brand reputation is in your hands.

Building Strong Supplier Relationships:

Communication: Maintain open and regular communication with suppliers. Clear expectations and feedback can lead to improvements and more efficient service.

Partnerships: Treat suppliers as partners rather than just vendors. Collaborative relationships can lead to better pricing, priority service, and access to the latest materials and innovations.

Ethical Practices: Choose suppliers who adhere to ethical labor practices. This not only aligns with global standards but also appeals to brands that prioritize corporate social responsibility.

Establishing Efficient Production Processes

With a robust material sourcing strategy in place, the next critical step for an OEM clothing manufacturer is to establish efficient production processes. Efficient production not only maximizes productivity and profitability but also ensures that the final products meet the quality standards expected by clients.

Streamlining Production Workflow:

Layout Optimization: Design your production floor for maximum efficiency. Place equipment and workstations in a logical sequence that aligns with the flow of garment manufacturing to minimize movement and handling.

Process Standardization: Develop standard operating procedures (SOPs) for every aspect of production to ensure consistency and quality. This includes cutting, sewing, finishing, and quality control.

Lean Manufacturing: Implement lean manufacturing principles to minimize waste and improve efficiency. Techniques like just-in-time (JIT) inventory can reduce excess stock and free up capital.

Leveraging Technology:

Automation: Invest in technology where it makes sense, such as automated cutting machines or sewing robots, to increase speed and precision while reducing labor costs.

Production Management Software: Utilize production management software to track progress, manage inventory, and streamline communication across different departments.

Quality Control:

Quality Assurance Systems: Establish a rigorous quality assurance system with checkpoints at various stages of production. This will help identify and correct issues before they become costly mistakes.

Employee Training: Invest in regular training for your employees to maintain high-quality craftsmanship and to stay updated with the latest manufacturing techniques and standards.

Scalability:

Flexible Production Lines: Design production lines that can be easily adjusted for different products or order volumes, allowing you to handle a range of orders without significant downtime or reconfiguration.

Capacity Planning: Monitor production capacity and have a plan for scaling up when demand increases. This may involve investing in additional equipment or hiring more staff.

Ethical and Sustainable Practices:

Worker Welfare: Ensure a safe and healthy work environment for your employees, with fair wages and reasonable working hours. This not only complies with ethical standards but also contributes to employee satisfaction and retention.

Environmental Impact: Look for ways to reduce the environmental impact of your production processes, such as water recycling systems, energy-efficient machinery, or reducing chemical use.

Building a Strong Brand and Marketing Strategy

For an OEM clothing manufacturer, a strong brand and effective marketing strategy are essential to differentiate your company in the competitive marketplace. Your brand is the identity of your business and communicates your values, quality, and professionalism to potential clients. A strategic marketing approach ensures that your brand reaches the right audience and converts them into customers.

Developing Your Brand Identity:

Brand Vision and Values: Define what your brand stands for and the values that underpin your business practices. This could relate to quality craftsmanship, sustainability, innovation, or customer service excellence.

Logo and Visual Elements: Design a professional logo and visual elements that represent your brand's identity. Consistency in these visuals across all touchpoints will help to build brand recognition.

Brand Messaging: Craft a compelling brand message that communicates your unique selling proposition and resonates with your target audience.

Effective Marketing Strategies:

Digital Presence: Establish a strong online presence with a professional website that showcases your capabilities, past work, and client testimonials. Utilize search engine optimization (SEO) to increase visibility.

Social Media: Leverage social media platforms to engage with your audience, share behind-the-scenes content, and promote your manufacturing services.

Trade Shows and Events: Participate in industry trade shows and events to network with potential clients and showcase your products and services.

Content Marketing: Use content marketing, such as blogs, videos, and white papers, to demonstrate your industry expertise and provide value to your audience.

Advertising: Consider targeted advertising in industry publications or online platforms to reach potential clients actively looking for OEM manufacturing services.

Sales Strategy:

Sales Team: Build a skilled sales team that understands your brand and can effectively communicate the benefits of your services to potential clients.

Client Relationships: Focus on building long-term relationships with clients through excellent communication, reliability, and consistent delivery of quality products.

Customer Service: Provide exceptional customer service to address client needs promptly and maintain a positive reputation in the industry.

Measuring Success:

Analytics and Metrics: Utilize analytics tools to track the success of your marketing efforts. Key performance indicators (KPIs) might include website traffic, lead generation, conversion rates, and client retention.

Feedback and Adaptation: Regularly seek feedback from clients and use this information to refine your marketing strategies and improve your services.

Managing Client Relationships and Orders

Success in the OEM clothing manufacturing industry isn't just about producing quality garments; it's equally about managing client relationships and orders effectively. This chapter explores strategies for maintaining client satisfaction, handling orders with precision, and fostering long-term partnerships.

Prioritizing Client Communication:

Clear Communication Channels: Establish clear lines of communication with clients, whether through a dedicated account manager, customer service team, or direct access to production management.

Regular Updates: Keep clients informed about the status of their orders, any challenges encountered, and the solutions being implemented.

Order Management:

Order Tracking Systems: Implement an order tracking system to manage the entire lifecycle of each order, from initial receipt to final delivery.

Accurate Documentation: Ensure all client requirements are well-documented and easily accessible to all relevant team members to avoid misunderstandings or errors in production.

Building Trust through Transparency:

Openness: Be transparent with clients about your production capabilities, timelines, and any potential limitations.

Honesty in Problem-Solving: If issues arise, communicate them promptly to the client along with proposed solutions, showing your commitment to resolving the matter efficiently.

Customization and Flexibility:

Tailored Services: Offer customization options where feasible to meet unique client needs, setting your business apart from competitors.

Adaptability: Be ready to adapt to changes in client demands, whether it's rush orders, design changes, or fluctuating order quantities.

Feedback and Continuous Improvement:

Soliciting Feedback: Actively seek client feedback to understand their experience and identify areas for improvement.

Implementing Changes: Use client feedback to refine your processes and enhance service delivery, demonstrating a commitment to continuous improvement.

Nurturing Client Relationships:

Value-Added Services: Offer services that add value beyond the basic manufacturing process, such as design assistance, material sourcing, or logistics support.

Client Appreciation: Show appreciation for your clients' business through loyalty discounts, personalized services, or simple acknowledgments of important milestones.

Leveraging Technology:

Customer Relationship Management (CRM) Tools: Utilize CRM software to manage client interactions, store important client information, and analyze data to better understand client needs.

Collaboration Platforms: Employ collaboration platforms that allow for real-time updates and sharing of information to improve the cohesiveness of client-manufacturer workflows.

Scaling the Business and Exploring New Opportunities

As your OEM clothing manufacturing business matures, scaling up and identifying new opportunities become paramount to ensure continued growth and success. This chapter will discuss strategies for expansion, exploring new markets, and continuously innovating to stay ahead in a competitive industry.

Strategic Planning for Growth:

Assessing Capacity: Evaluate your current production capacity and identify what is needed in terms of space, equipment, and personnel to grow.

Market Analysis: Conduct thorough market research to identify new trends, demands, and potential niches that align with your business's strengths.

Expansion Methods:

Investing in Infrastructure: Consider investing in additional manufacturing facilities or upgrading existing ones to increase production capabilities.

Diversifying Product Range: Expand your product offerings to cater to different sectors within the clothing industry or to meet specific client requests.

Geographical Expansion: Explore opportunities in new geographical markets, which may involve setting up production facilities abroad or partnering with local distributors.

Innovating and Staying Competitive:

Research and Development: Invest in R&D to innovate new manufacturing techniques, materials, and designs that can set your business apart.

Adopting New Technologies: Stay updated with the latest manufacturing technologies and software solutions that can improve productivity and product quality.

Building Partnerships and Alliances:

Strategic Partnerships: Forge partnerships with other businesses that can complement your services, such as textile producers, designers, or logistics companies.

Industry Alliances: Join industry alliances to stay informed on best practices, regulatory changes, and sustainability initiatives.

Marketing for Expansion:

Targeted Marketing Campaigns: Develop marketing campaigns tailored to new markets or product lines to create awareness and generate interest.

Enhancing Online Presence: Update your website and online presence to reflect your expanded capabilities and reach a broader audience.

Financing Growth:

Funding Options: Explore different funding options to finance your expansion plans, including loans, investors, or reinvesting profits back into the business.

Financial Management: Ensure robust financial management systems are in place to handle the increased scale of operations.

Ensuring Sustainability:

Sustainable Practices: As you grow, maintain a commitment to sustainable manufacturing practices to meet both regulatory requirements and consumer expectations.

Community Engagement: Engage with the communities where you operate, supporting local initiatives and ensuring that your business has a positive impact.

-500x500.jpg)

-500x500.jpg)

-500x500.jpg)

-500x500.jpg)

-500x500.jpg)